The Goliath Project was a massive undertaking for Loenbro. True to its name, it required large equipment, large crews, and a healthy amount of determination. The project spans 10 miles north and 15 miles east and west and is located near the town of Ray, North Dakota. In the main section of the project, the right of way is over 50 feet wide, with an 8-foot ditch width. In the ditch are four pipes of varying sizes and materials. The main line is a 12-inch steel pipeline, which is flanked by a 12-inch polyurethane, 8-inch steel, and 6-inch steel line. The ditch is dug to over 9 feet deep, and at final grade the lines will be buried 8 feet deep. This project required massive resources, including a fleet of dozers, excavators, graders, side-booms, semi-trucks, and other support equipment and manpower. The largest equipment were 47-metric-ton excavators, D8-class dozers, and a specialized machine made for separating padding material for the pipeline.

What makes it interesting?

The reason this project is so challenging comes from the length, number and size of pipelines, and resources needed to accomplish. At project completion, more than 500,000 feet — or 95 miles — of ditch will be dug. This equates to almost 900,000 yards of material moved and over 250 miles of pipe laid in the ground.

How HCSS Software assisted with this project

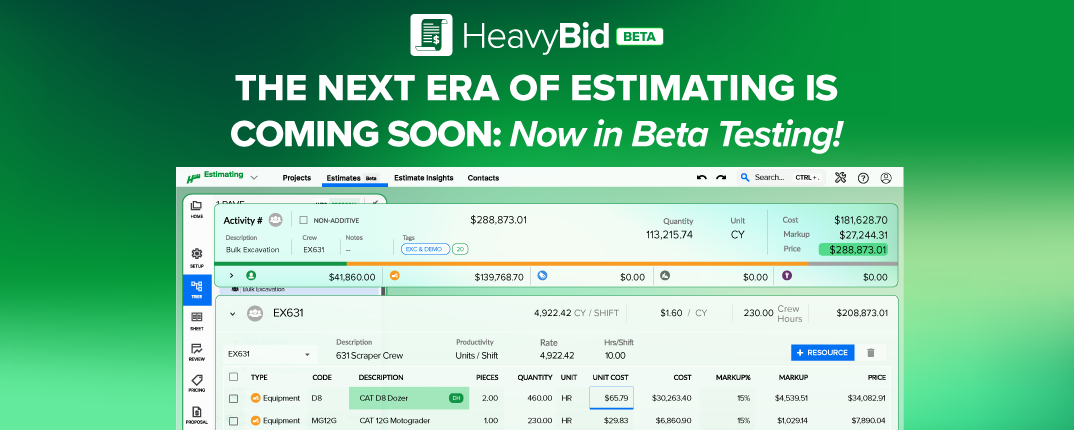

The time, material, equipment, and manpower were managed through a collaboration of HCSS software, including HeavyBid, HeavyJob, HCSS GPS, and Equipment360. With such a massive project, the pipeline software systems easily showed their advantage to older methods such as paper time cards, spreadsheets, and pin boards.