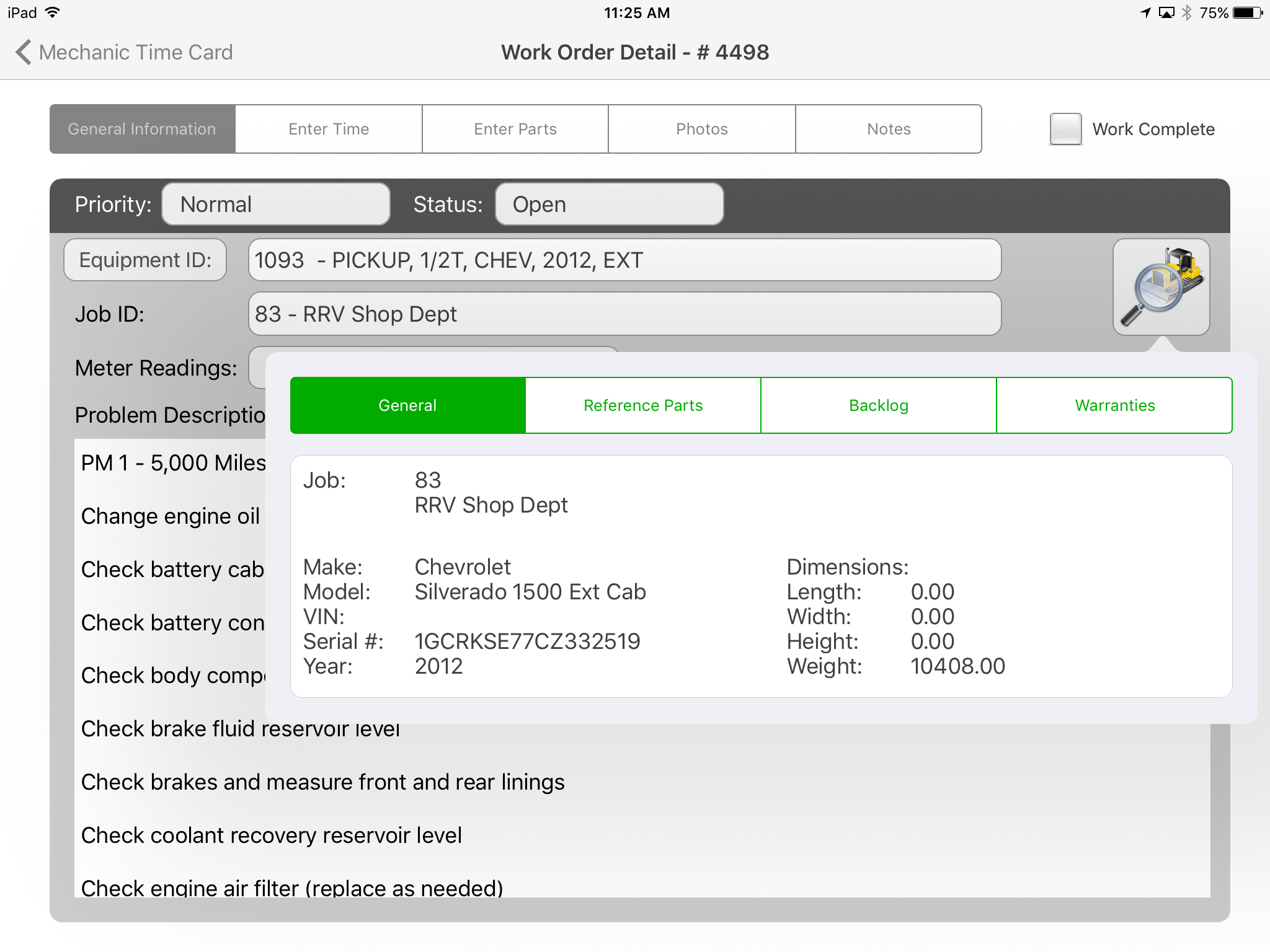

Mobile Mechanic gives your mechanics a checklist for each work order and provides an easy way to record meter hours and enter time, parts, and notes.

At The Earle Companies in Wall, N.J., manual workflows in the service department are now being transformed into a model of efficiency as tablets replace the paperwork in files and cabinets of an archaic system.

“We are changing to a paperless service department in order to stay ahead of the curve and make our shop more efficient,” said Brian Cooper, P.E., engineering department manager and product manager.

Equipment360 is helping eliminate manual data entry for work orders, time cards, and equipment inspection reports by putting everything at the service technicians’ fingertips. “It’s streamlining and simplifying the process,” he added. “Plus it is providing a morale boost to our guys, especially the younger ones.”

HCSS Equipment360 Helps Shops Shift From Reactive to Proactive

For decades, machine maintenance throughout the industry was mostly reactive. When a piece of equipment broke down, the shop manager would locate or order parts and assign a mechanic to do the repair, and the mechanic would keep track of the hours spent on the fix using a paper ticket. Then those paper work orders and tickets made their way back to the office for manual entry, allowing payroll to cut checks and managers to assign repair costs against equipment. With Equipment360, “there’s no more manual data entry. Our guys are taking care of this themselves,” commented Cooper.

With manual methods, unless the mechanic had personal experience with the equipment, there was no way to know its history, if other items on the machine were up for repair, or if the fix was a warranty issue. But now the entire work and repair history of each piece of equipment is stored within Equipment360, giving the technician a full picture of the equipment being maintained. “The program is so simply designed, it’s easy to enter data,” he continued. Plus, the program can serve as a single platform for a wide range of equipment telematics reporting. “We have nearly 400 pieces of equipment from several manufacturers, and all the telematics reports into Equipment360 seamlessly,” explained Cooper.