You can’t operate a job site without equipment. For many heavy civil construction companies, it’s the largest asset they own. Therefore, it can have a profound impact on your bottom line. While there are many fleet performance metrics to manage in order to keep a fleet productive and healthy, we’ve listed 5 metrics below that have a direct impact to the bottom line.

Metric #1: Utilization

Utilization is defined as a measure of use of a machine unit or a class of machines, i.e., 40 hours/week equates to 2,000 hours/year. If that is the maximum time of usage, that becomes 100% utilization.

Equipment is one of the largest assets of any heavy civil construction company. For example, it’s not uncommon to have a million dollars worth of equipment on a $150,000 job. So, every fleet manager wants to make sure they are utilizing each of those assets to its fullest potential. Utilization also becomes a key data point in determining equipment rates, so it’s important that it’s accurate.

Comparing “charged time” to a job, entered by field personnel, with “actual machine hours”, from telematics or manually entered, can help you determine how your fleet is really doing. You’ll want to set utilization target expectations for each equipment class, i.e., mid-size excavators may be 1,300 hours/year (65%), while asphalt machines may be 1,900 hours/year (95%). The better utilization rates you can achieve, the less equipment is sitting around idle costing you money. And, that means more profit for your company.

How can HCSS help with utilization?

HeavyJob entries track “charged time” from the field.

HeavyJob entries track “charged time” from the field.

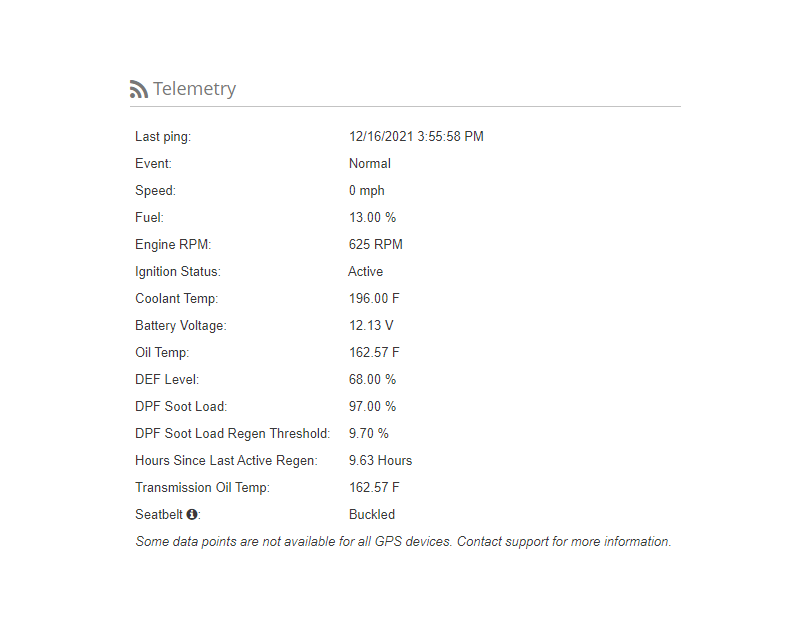

- HCSS Telematics tracks your “actual machine hours”.

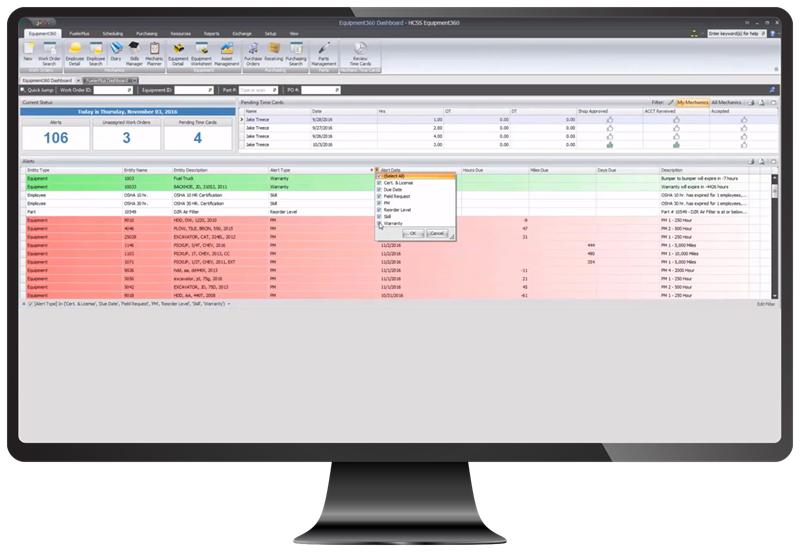

- Equipment360 shows you which pieces and classes of equipment are underutilized in your fleet.

Metric #2: Equipment Rates

An equipment rate is a rate set to use a piece of equipment – a dollar amount per specified time period.

Equipment rates are a useful metric that allows companies to bid on their expected equipment cost, recover their costs/investment, and compare internal equipment costs with published outside rental/lease costs to validate ownership versus renting. They typically include all fixed, ownership costs, and operating costs. They should not include operator and accident/abuse repairs. It is typically recommended to set rates by class, and you might consider having rates for “idle” (ownership costs only), “running” (ownership and operated costs), “down”, and “stored”.

The challenging part about setting equipment rates is that there is no “right” way to do it. Also, they should be dynamic to account for changes in utilization, purchase prices, fuel costs, etc. – which means they should be revisited at least bi-annually. While an executive like a CEO, COO, or owner typically has the final say on equipment rates, high-performing Equipment Managers track their costs to be able to give data-backed recommendations.

How can HCSS help with equipment rates?

Equipment360 helps you keep track of your shop and equipment costs down to the penny. In addition to cost categories like operating vs. ownership, you can filter and sort by cost subtypes, repair vs. maintenance costs and more. And, you can display costs in different ways like “per meter hour” or “per utilization hour”.

Metric #3: Uptime Hours

Uptime hours are the hours that a piece of equipment is available to be used during regular shift hours. The opposite of “downtime hours” which indicates a piece of equipment is unusable, due to needing an unplanned repair.

Whether you track uptime or downtime, it’s a very valuable metric because it allows Equipment Managers to evaluate their brand/model choices, their preventive maintenance programs, their rebuild programs, their replacement process, their assigned operator program and more.

Downtime calculations should include only normal wear and tear repairs and should exclude planned “off-shift” repairs. It’s those planned repairs like those included in a preventive maintenance schedule that lead to more uptime, which leads to more projects completed on time and on budget for the company.

How can HCSS help uptime hours?

HCSS Telematics gives mechanics and service teams access to fault codes which can help decrease machine downtime by letting them know what items they will need before they even leave to do the repair. Equipment360 supports robust preventive maintenance programs, allowing you to “play offense” and be proactive towards increased uptime hours.

Metric #4: Wrench Time

Wrench time is the time a mechanic or technician spends with a tool in their hand, performing actual maintenance work.

No employee can spend 100% of their time on only direct labor or billable hours. And the same is true for mechanics. In the best shops, direct labor (i.e., wrench time) maximums are estimated somewhere between 60-85%, with the remaining time spent on indirect, but necessary things like clean-up time, sick/vacation time, training, redo work and maintenance/repairs on facilities and tooling.

But you don’t want to chip away at that wrench time even further with inefficiencies like difficulty locating equipment history/details, calling several people for information on a work order or repairing a piece of equipment only to find it back in the shop a week later for its scheduled maintenance.

Finding ways to reduce inefficiencies will get your mechanics more wrench time and, in turn, allows your company the scalability to do more without increasing headcount.

How can HCSS help with wrench time?

Equipment360 helps shops eliminate paperwork and increase communication. Mechanics have a “digital filing cabinet” with all the information they need at their fingertips.

Metric #5: Age Balance

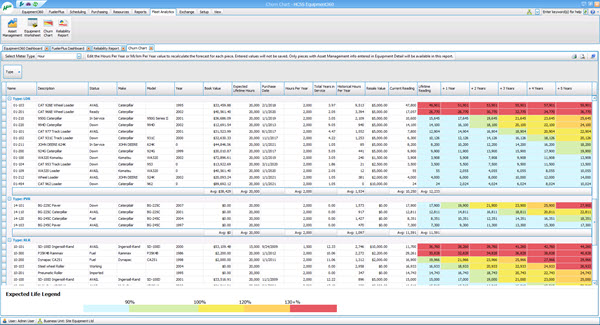

Age balance is replacing a portion of each class of equipment each year so that the average unit is at the midpoint of the projected class life.

Nothing lasts forever…including equipment. At some point, it will need to be replaced by purchase, rental purchase option, lease, rent or other means. But, just as your equipment was not likely all acquired at once, you won’t want to replace it all at once either. So, it’s important to have a mixed-age fleet at any point in time in order to avoid large capital outlays or delays in availability.

This is especially important in large unit classes and critical pieces for operations like large excavators and plant loaders. Keeping your fleet age balanced will help your company maintain capacity and stabilize cash flows related to equipment costs and purchases.

How can HCSS help with age balance?

Equipment360 features an easy-to-read Churn Chart, modeled after the CEMP color-coded method. In one glance, Equipment Managers can see whether specific equipment classes or their fleet on a whole is starting to skew away from a healthy age balance.

Do you need help managing these metrics, among others?

Once your company reaches a certain size, your team’s ability to track, manage and report on these fleet performance metrics becomes difficult without the help of software. HCSS offers several products, specifically designed for the heavy civil construction industry, that help you across every aspect of your business.

Contact us to connect your office, field, and shop so you can do more with less.