This isn’t your local, two-bay mechanic shop. We’re talking about an entire fleet of trucks, pavers, loaders, compactors, and cranes — each with its own exhaust system, steering, and safety checks.

And you think your Excel spreadsheets can precisely track everything and keep you efficient enough to win in this competitive market? Spreadsheets are just a direct replacement for stacks of paper on your desk. You deserve an intelligent solution that can free you to manage your fleet, not your spreadsheets.

A well-oiled construction company depends on its fleet vehicles to accomplish daily operational goals. From knowing where the assets are and how they’re performing to proactively maintaining them, it’s crucial to have the data and technology to keep these money-makers on the road.

Your fleet management software could completely revolutionize how you operate. What once was seen as a “luxury” has become a necessary tool for maintaining a high-quality fleet.

What is Fleet Management Software, and How The Heck Does it Work?

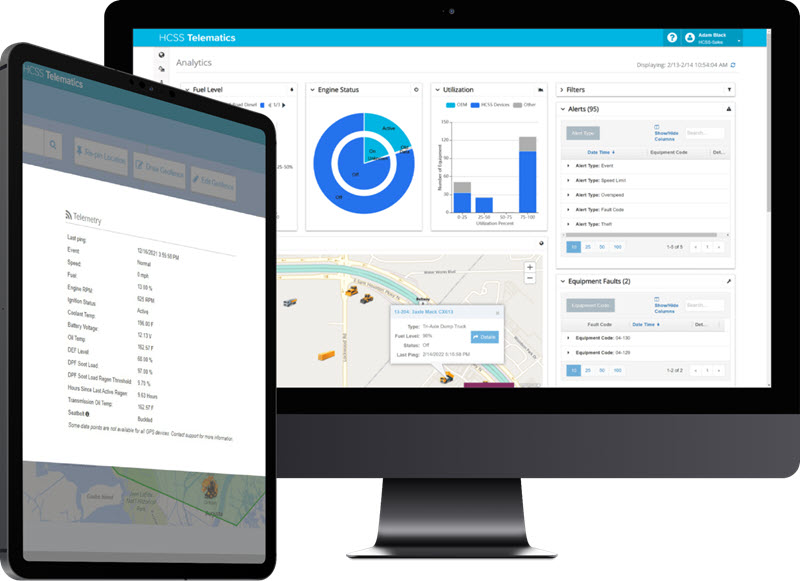

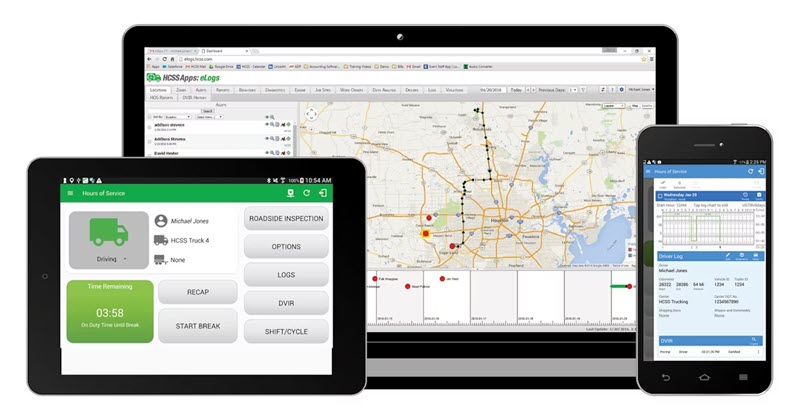

Fleet management software allows the fleet manager to have eyes on every piece of equipment. From vehicle performance & maintenance to driver behavior and compliance, this software uses telematics technology to capture all your fleet data. Things like:

- Equipment location

- Maintenance alerts

- Low parts inventory alerts

- Parts utilization tracking

- Fuel tracking/costs

One of the most vital parts of fleet management software is actionable insight. Once it collects real-time data directly from your equipment’s ECU, it shoots that over to you and your team to identify improvements or discover inefficiencies within the equipment. Typically, the bigger your fleet, the more difficult it is to transfer, organize, and decipher the data — but with the right fleet management software, you could potentially cut your time and costs in half!

Inflation & High Costs WILL Eat Up Your Fleet Business

Even with the passing of some favorable laws like the Infrastructure Investments & Jobs Act (IIJA), Inflation Reduction Act (IRA), and the Creating Helpful Incentives to Produce Semiconductors (CHIPS) Act, many construction companies are still feeling the tightness in their chest from significant cost pressures.

Fleet management costs like maintenance, insurance, and fuel haven’t exactly eased up over the past few years. From the oil changes to your run-of-the-mill tire replacements, these cost fluctuations often lead projects down a road full of disruptions, delays, and terminations.

All of which eat into your fleet's bottom line.

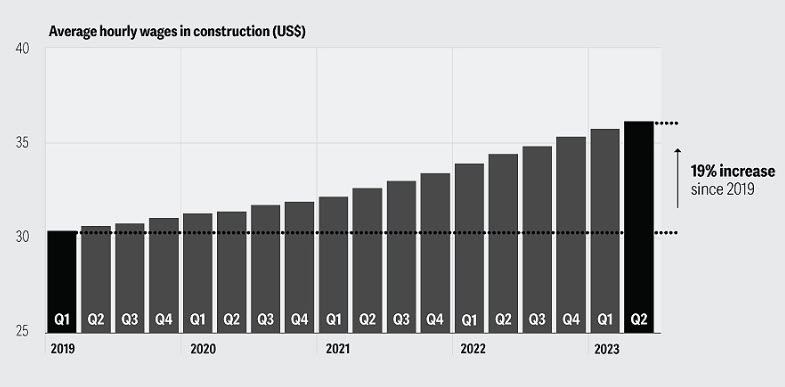

Not to mention, according to the U.S. Bureau of Labor Statistics, the average hourly wage in construction has increased by 19% since 2019. Construction wages are only expected to rise moving forward. Just some more numbers to keep in mind.

Considering all these costs, it can be easy to fall into the rabbit hole of inefficiencies and begin rattling off ways to cut back. This is why fleet management software is essential — it’s designed to trim the fat off your operations and allow you to run at a higher clip.

Better Data, Better Decisions

With HCSS Telematics, for example, you can manage the health of your entire fleet before they ever leave the lot. Data is king in this industry, especially when it comes to your equipment. So, if you can use data to stay proactive rather than reactive in the field, you win. Along with being a powerful GPS tracker for all fleet equipment, our Telematics software is designed to feed you critical machine data straight from the ECU — this way you and your team can make decisions within days (possibly minutes if you’re quick enough), not weeks.

Why let a month’s worth of wear and tear pass before discovering your diesel filters are full of soot? Your fleet management software is designed to decrease your equipment downtime and help you cut the costs that come with it.

Other ways HCSS Telematics keeps more money in your pocket:

Dashcams

Unfortunately, accidents happen on the field. Whether equipment-related or driver-related, dashcams help cut some of those costs. Not only do they serve as a monitor for potentially bad driving, but they also help with the occurrence of accidents and (more importantly) the insurance costs that come with those.

Electronic Logging Device (ELD)

Fleet compliance. Is it vital to your operations? Yes. Is it at the top of your mind? Maybe not. Our ELD software automatically complies with FMCSA regulations, including ELD reporting and engine synchronization requirements so you won’t have to worry about paying those costly fleet compliance penalties.

Preventive Maintenance Could Be the Difference Between a Repair and a Rebuild

Preventive maintenance is your best shot at reducing, even avoiding, equipment breakdowns. When managing an entire fleet, proactivity is the name of the game, so keeping up with your equipment before it needs servicing could be the difference between a light tune-up and a costly rebuild.

Your preventive maintenance is based on calendar days, run-time hours, and the equipment’s mileage. With software like Equipment360, you can easily set up predefined thresholds to automatically trigger activities like vehicle inspections, cleaning, part replacements, or other ongoing maintenance activities when met. This automation keeps you and your fleet operating with maximum uptime and ensures your fleet equipment lasts longer.

Now, for the dark side of preventive maintenance.

What happens when you don’t have a software or plan in place? What could the future of your fleet look like then?

Equipment Repairs

On the shallow end of the “how much will this run me?” spectrum you have ‘equipment repair.’ If most of the equipment works fine except for a few parts acting up, it makes sense to fix those bits instead of splurging on a whole new setup. This is especially smart if the warranty's still valid or you haven't finished paying off the equipment yet. Repairs usually beat out replacements because they're quicker and cheaper, especially if you have on-site technicians who can swing by and sort it out.

Additionally, Equipment360 can create detailed work orders to track your equipment history and maintenance costs down to the penny. This allows you to improve your operations after the repairs.

Equipment Rebuild

Unlike equipment repairs, you’ll feel rebuilds much more. Without reliable preventive maintenance or fleet management software, you’ll find yourself constantly shelling out for minor (preventable) repairs, and the bill keeps piling up. Eventually, you’ll get to a point where a rebuild is the only viable option.

Equipment rebuilds are not just about patching things up here and there. When you rebuild, you swap out old, busted parts for shiny, expensive, new ones. You’re paying a pretty penny to hit the reset button on your equipment’s lifespan. Along with all these costs, you must also plan for equipment downtime and potential replacement rental costs.

Stay Miles Ahead of the Competition

Whether that means reducing operational costs or improving equipment utilization, high-quality fleet management software is vital for gaining the upper hand on the competition. Luckily, most construction companies in the industry still rely on manual tracking and lagging programs to maintain the entire fleet.

A costly decision for a couple of reasons:

Overutilization and Underperformance

Efficiency is key! Without reliable fleet management software, construction companies often struggle with over & underutilization of equipment. They’re ill-equipped to accurately get a read on their fleet.

With HCSS Telematics and Equipment360, you not only have data on all your equipment, but you can see utilization rates, remaining equipment life, and equipment cost to make informed budgeting and equipment purchasing decisions — everything you need to stay as efficient as possible.

Fuel Guessing Game

Fuel costs take up a good portion of operational costs, and with inflation rising, there’s no telling how much you could be spending. Without real-time data and cost analysis, construction companies simply estimate their spending using a formula that divides the total fuel cost by the equipment's productive time to calculate the hourly fuel cost. Not very cost-effective.

With FuelerPlus and HCSS Telematics, you can track every drop of fuel that goes through your fleet. From fuel dispenses and purchases to actual fuel burn rates — our fleet management software allows you to use real-time data to decide how you want to recoup that cost from operations. Tracking fuel costs is a must for project profitability; fleet management software will keep you on budget.

Ready to Give Your Fleet an Upgrade?

No need to get bogged down with the manual side of fleet management. Let HCSS show you the future of fleet with our Telematics, FuelerPlus, and E360. To learn more about our fleet management software, book a demo and find out how you can maximize your operations and stay ahead of the competition.