Kwest Group Keeps Growing +10% Every Year: How HCSS Data Helps Make This Happen

“We have been using [the] HeavyBid and HeavyJob programs for a long time, along with the entire suite. The relationship with HCSS has been amazing from day one. The support and the service has been top-notch – never been a thought to ever go any place else. HCSS has been a humongous factor in our growth and our success.”

- Nick Young, Director of Preconstruction

One trend you’ll often notice when doing a deep dive on HCSS customers is an exponential growth rate that’s nothing short of impressive. A shining example of this is no doubt Kwest Group.

“We’re a very, very rapidly growing company, and we react to that really well,” says Nick Young, Director of Preconstruction. “We are averaging 10% a year growth. Some years are greater, some years are a little bit less.”

Thanks in part to all of the technology that Kwest Group has implemented, it’s incredibly easy to see why they are a true industry leader. With their unique, API-driven approach, the use of the full HCSS platform alongside the company’s self-developed software (called Kwest PLAN) has helped them leverage data to meet that coveted 10%+ annual growth rate goal.

Accelerating Performance with the HCSS Platform

Headquartered in Ohio, Kwest Group has grown to employ over 450 team members and is licensed to perform work in over 45 states – primarily carrying out heavy civil and environmental projects.

“We started with HeavyBid and HeavyJob from day one,” says Vice President of Integration, Dan Tack. “Those products have been in use and they’ve been the backbone.”

Kwest Group proceeded to implement the entire platform on the unlimited user plan, which includes HCSS Safety and Equipment360. Their team has also recently begun working more heavily with HCSS Plans to ensure every worker has access to digital prints on the jobsite. “The day-to-day impact of HCSS and the products is it allows us to have real-time data,” Tack continues. “Our project management team analyzes that data. It allows us to make sure a job is staying on track.”

Implementing technology to connect the field to the office has completed a full circle for Kwest Group, enhancing widespread communication amongst all of their people.

“We avoid delays on our projects using data,” Tack says. “The more data we receive the faster we can react. To avoid rework, the data is available to our superintendents, our general superintendents, and our project management team. They can see what the foreman is talking about. They can also see if the foreman is providing the quality project promised to our client in advance. HCSS software has made that possible, to have that communication.”

As everyone involved in the industry knows, adjusting on the fly is a must for any contractor, and lost time means lost money. At a granular level, Kwest Group primarily uses HCSS to track all job costing, connecting the software to their financial system to perform more accurate forecasting.

“We’ve been able to leverage the data coming from HeavyBid into HeavyJob and ultimately Kwest Plan,” says Nick Young, “as a means for our field operations people to be able to plan their work more efficiently, more accurately, to adjust to the change, which happens every day. And for us to forecast our revenue and man hours down the road, which is something we were not able to do very accurately prior to Kwest Plan and then the implementation with HeavyBid and HeavyJob, those components alone have been huge for us. We’re just simply smarter on what we now know and it allows us to adjust to change very quickly.”

Over 4.3 Million Work Hours Without a Lost-Time Incident

Being an award-winning company on the safety side, Kwest Group has reached an impressive milestone of 4.3 million man-hours without a lost-time incident. Courtesy of their six-step safety program, this achievement reflects highly on the organization’s steadfast commitment to employee well-being.

“I think it’s time that we acknowledge software and our ability to use technology, and that has contributed to those award-winning efforts,” says Dan Tack. “Using HCSS and using our self-development platform has made us who we are. Every day it’s used. Every computer you would look at in our operational area has HCSS and Kwest Plan up. I guarantee – right now. It’s allowed us to definitely increase our revenue and our profitability. Without it, I honestly do not know how we would operate. It is definitely the backbone of our company.”

Kwest Group’s emphasis on their safety program has been an incredibly high priority since the company’s inception. “That’s why our clients typically hire us,” Tack states. “They want a safe civil contractor.”

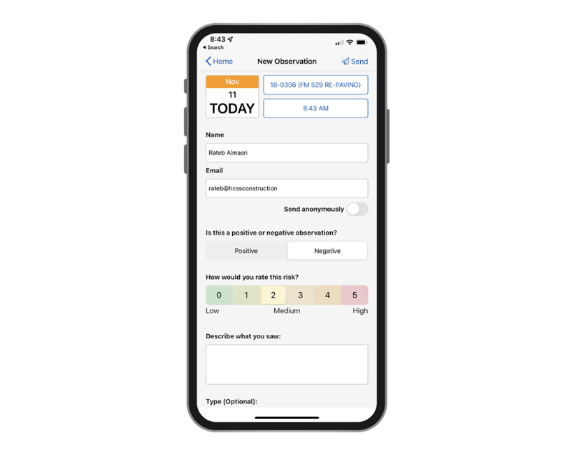

With HCSS Safety becoming a key part of Kwest Group’s safety culture, the most noticeable improvement to their program has been the ability to track key metrics and leading indicators.

“The nice part of HCSS is we can analyze in advance what the risks are on that jobsite based on historical trends and be able to take that data and mitigate a lot of hazards,” Tack outlines. “The other thing it does is give us real-time data if the employees are doing what they are supposed to be doing. Every day, our employees are required to do a safety inspection on the piece of equipment they’re going to operate. Every day, they’re supposed to do a self-inspection on their readiness and make sure they’re ready to work. Then we do the collective risk analysis for the job and we record it all in HCSS. Those acts allow us to ensure that the team is putting safety in the forefront of their thoughts, starting the day off right.”

With safety ultimately existing as the be-all and end-all of a construction company, Nick Young couldn’t be prouder of what they’ve accomplished in terms of an effective safety program.

“Safety is absolutely paramount and number one for Kwest Group,” he comments. “A lot of companies say that, but Kwest group absolutely lives it. It’s been proven with our current 4.3 million man-hours without a lost time incident. That is a real number. Not many companies, regardless of size, can say that. So we live and breathe that every day.”

WHO:Kwest Group

WHERE:Perrysburg, OH

INDUSTRY:Energy/Renewables, Petrochemical/Industrial

SOLUTIONS:Estimating, Project Management, Safety, Fleet Management

“Technology has definitely influenced our profitability, our ability to meet our customers’ needs. Being spread over 45 states and doing different jobs, without technology, we would not be able to service the customer the way we do now. It totally enables us to be more profitable and, honestly, flexible.”

- Dan Tack, Vice President of Integration

Ramping Up Equipment Operations

As their Equipment Operations Coordinator, Brooke Speiser has been with Kwest Group for 8 and a half years. Before moving over to equipment, she initially started in the estimating department, putting together bids.

Being a civil contracting company with operations in 11 states at any given time creates multiple challenges for any fleet. The equipment department originally began using a fairly straight-forward app before realizing they could implement something more powerful.

“I work heavily in E360,” Speiser says of the trademark fleet management software from HCSS, Equipment360. “When we developed our Kwest Plan with the APIs from all of the different HCSS products, we could communicate with the field even more directly and streamline our process.”

Speiser is upfront in stating how their expansion of these technology resources – and adding more HCSS products – has been instrumental to the company’s expansion. From getting work orders over to mechanics easily for quick completion to improving utilization time on equipment, the effects are far-reaching in everyday operations.

“Technology helps us to make more informed decisions in a timely manner because we have everything in one place,” Speiser adds, “Anytime [our field members] need something, they’re sending it to us and we’re receiving it immediately. We can get it to them exactly when they need it. A lot of times the jobs are changing in a minute’s notice and we’re able to react and solve the problem instantaneously.”

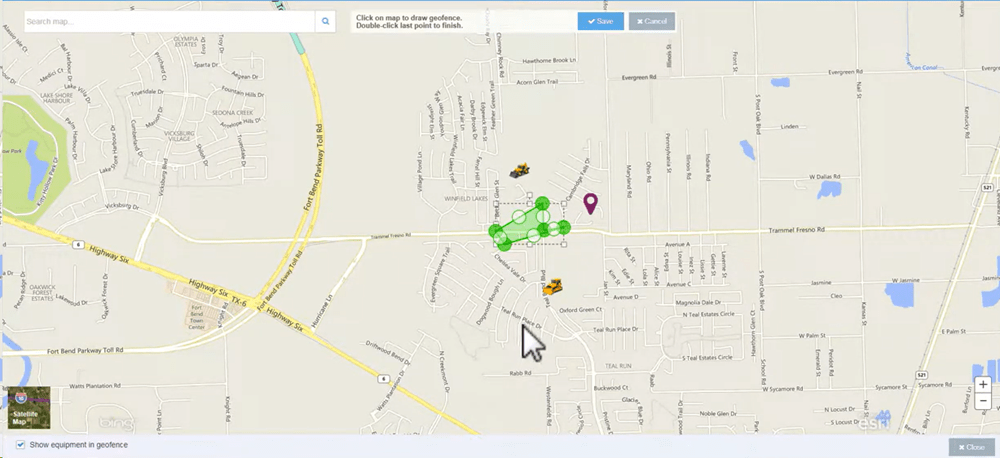

For example, if a Kwest Group crew needs a piece of equipment on a jobsite on day one, and then they need to change that work order on the third day, the team can plan ahead using the APIs from HCSS. Based on equipment activity in Telematics and time card entries in HeavyJob, everything can be tracked. In fact, Kwest even went so far as to create a system where – if the time card and the Telematics location isn’t matching up – it immediately gets flagged so they know something isn’t right. Doing this to eliminate transportation and rental costs has been a huge cost-saver for the company.

“Within the equipment department, it’s exciting to see how far we’ve come with the technology just in the time that I’ve been here,” Speiser says. “We’ve had two units stolen this year that we’ve been able to recover immediately because of Telematics, so it’s paid for itself just within those two pieces of equipment. We could have just easily lost those and lost hundreds of thousands of dollars in equipment overnight.”

All in all, Kwest Group’s revised equipment strategies – including a 75% in-house to 25% outsourced ratio with major dealerships – enabled their business to cut significant costs on maintenance and fuel, plus drastically reduce downtime, as well as take environmental considerations into account using HCSS Telematics. The result has been growing their fleet, streamlining processes, and saving an estimated 7 figures in expenses.

Continuing to Grow Year After Year

With such an effective set of processes in place, it doesn’t look like Kwest Group is going to be slowing down anytime soon. The most important lesson that can be learned from their upward trajectory is not only to dismiss fear of technology – but to openly embrace all of the opportunities the digital movement offers.

Grow your business with HCSS

Fill out the form to see how our software solutions can help you throughout each stage of the project lifecycle